Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Specific Safety Considerations when Using Universal Couplings

Universal couplings are essential components in many mechanical systems, and their proper use is critical for the safety of personnel and the integrity of the equipment. Here are some specific safety considerations when using universal couplings:

- Regular Inspections: Perform routine inspections of the universal coupling to check for signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent potential accidents.

- Proper Installation: Ensure that the universal coupling is installed correctly and securely. Follow the manufacturer’s guidelines and torque specifications for tightening bolts, set screws, or clamps.

- Shaft Locking Mechanisms: If the universal coupling uses set screws or clamps to secure the shafts, ensure that these locking mechanisms are adequately tightened and checked periodically to prevent shaft slippage during operation.

- Correct Coupling Selection: Choose the appropriate universal coupling based on the specific application’s torque, speed, and misalignment requirements. Using an undersized coupling can lead to premature failure and safety hazards.

- Misalignment Limits: Stay within the manufacturer’s specified misalignment limits for the universal coupling. Excessive misalignment can lead to increased stress on the coupling and connected components, potentially causing failure.

- Guarding and Enclosure: If the universal coupling is exposed or accessible to personnel, consider installing guarding or enclosures to prevent accidental contact and reduce the risk of injury.

- Training and Awareness: Ensure that personnel working with or around machinery equipped with universal couplings receive proper training and understand the potential hazards associated with these components.

- Maintenance and Lubrication: Follow a regular maintenance schedule and lubricate the universal coupling as recommended by the manufacturer. Proper lubrication reduces friction and wear, contributing to safe and reliable operation.

- Emergency Stop: Equip the machinery with an emergency stop system that allows operators to quickly shut down the equipment in case of an emergency or abnormal condition.

- Consult the Manufacturer: If there are any concerns or questions about the safety aspects of using a universal coupling in a specific application, consult the manufacturer or a qualified engineer for guidance.

By adhering to these safety considerations and implementing proper installation, maintenance, and operational practices, the use of universal couplings can be safer and more effective in power transmission applications.

How do you calculate the required size and specifications for a half coupling?

Calculating the required size and specifications for a half coupling involves considering several factors to ensure a proper fit and secure connection. Here are the steps to calculate the required size and specifications:

1. Pipe Size: Determine the size of the pipe that the half coupling will connect to. Pipe sizes are typically specified in inches, and the half coupling size should match the pipe size.

2. Pipe Material: Identify the material of the pipe, such as stainless steel, PVC, carbon steel, brass, copper, etc. The half coupling material should be compatible with the pipe material to prevent corrosion and ensure a reliable connection.

3. Pressure Rating: Determine the maximum operating pressure of the system. The half coupling should have a pressure rating that meets or exceeds the system’s operating pressure to ensure safety and performance.

4. Temperature Rating: Consider the maximum and minimum operating temperatures of the system. The half coupling material and design should be suitable for the temperature range to prevent deformation or failure.

5. Alignment and Misalignment: Evaluate the alignment and potential misalignment between the pipes. Some half couplings are designed to accommodate angular, parallel, or axial misalignment, providing flexibility in installation.

6. End Connection: Determine the type of end connection required for the half coupling, such as threaded, weld-on, or flanged. The end connection should match the corresponding connection on the pipe.

7. Corrosion Resistance: Consider the environment in which the half coupling will be installed. For corrosive environments, select a half coupling material with suitable corrosion resistance.

8. Industry Standards: Ensure that the selected half coupling complies with relevant industry standards and certifications for quality and safety.

9. Manufacturer Guidelines: Follow the manufacturer’s guidelines and recommendations for selecting the appropriate half coupling size and specifications based on the application requirements.

It is essential to consult with coupling manufacturers, suppliers, or industry experts if you are unsure about the correct size and specifications for the half coupling. Proper sizing and selection will ensure a reliable and efficient connection in the piping system.

How does a Universal Coupling Work to Transmit Torque and Rotation?

A universal coupling, also known as a universal joint or U-joint, is a mechanical device used to transmit torque and rotation between two shafts that are not in a straight line and have angular misalignment. It allows for flexible coupling between the shafts, enabling power transmission even when they are at different angles to each other.

The basic design of a single universal joint consists of two yokes, each attached to the end of the shafts to be connected. The yokes are connected by a cross-shaped intermediate component, often referred to as the spider or cross. The spider has four arms, each fitting into a yoke, creating a flexible joint.

When one shaft rotates, the spider transmits the motion to the other yoke and, consequently, to the second shaft. This mechanism allows the universal coupling to handle angular misalignment between the shafts. The universal joint can accommodate small angles of misalignment, making it ideal for applications where the shafts are not perfectly aligned.

The double universal joint, also known as the double Cardan joint, consists of two single universal joints connected end-to-end with an intermediate shaft in between. This design reduces the angular variation between the input and output shafts, providing a smoother rotation and reducing vibration in certain applications.

The constant velocity joint (CV joint) is a specialized type of universal joint that maintains a constant velocity ratio between the input and output shafts. It is commonly used in automotive drive shafts to provide smooth power transmission, especially in front-wheel-drive vehicles, where the drive shafts must adjust to changing angles as the wheels turn.

Overall, universal couplings are essential components in various mechanical systems, especially in vehicles, industrial machinery, and power transmission applications. They allow for flexible power transmission while compensating for misalignment, making them a versatile and widely used coupling solution.

editor by CX 2024-05-06

China Best Sales Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling universal coupling

Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CZPT requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

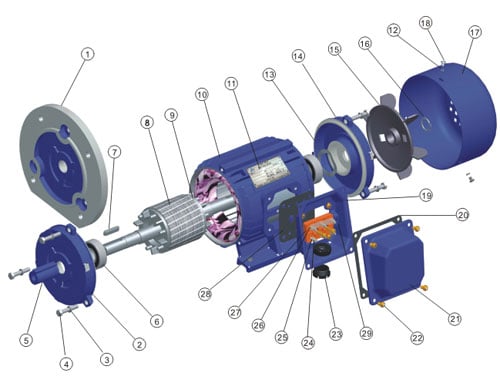

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

Are there Maintenance Requirements for Universal Couplings to Ensure Longevity?

Yes, like any mechanical component, universal couplings require regular maintenance to ensure longevity and optimal performance. Proper maintenance practices can help prevent premature wear, reduce the risk of failure, and extend the service life of the coupling. Here are some essential maintenance requirements for universal couplings:

- Lubrication: Universal couplings consist of moving parts, such as bearings and cross journals, which require proper lubrication. Regularly lubricating the coupling helps reduce friction, wear, and heat generation. The type and amount of lubrication needed depend on the coupling’s design and the manufacturer’s recommendations.

- Inspection: Regular visual inspections should be performed to check for signs of wear, damage, or misalignment. Look for any abnormal vibrations, noise, or leakage. If any issues are detected, they should be addressed promptly to prevent further damage.

- Torque Checks: It is essential to periodically check the torque of the coupling’s fasteners, such as bolts and nuts, to ensure they are properly tightened. Loose fasteners can lead to misalignment and coupling failure.

- Alignment: If the coupling is used in an application where misalignment is common, such as automotive drivetrains, it is crucial to check and adjust the alignment regularly. Proper alignment helps prevent excessive stress on the coupling and other connected components.

- Replacement of Worn Parts: Over time, certain parts of the universal coupling, such as bearings and seals, may wear out and need replacement. Following the manufacturer’s recommended service intervals and using genuine replacement parts is essential to maintain the coupling’s reliability.

It is essential to refer to the manufacturer’s maintenance guidelines and recommendations specific to the universal coupling model and application. Regular maintenance not only ensures the longevity of the coupling but also contributes to the overall efficiency and reliability of the machinery or system in which it is used.

How do Temperature and Environmental Conditions Affect Universal Coupling Performance?

Temperature and environmental conditions can have a significant impact on the performance of universal couplings in mechanical systems. The materials used in manufacturing the coupling and the operating conditions can influence its durability, flexibility, and overall functionality.

Temperature: Universal couplings are often made from materials such as steel, stainless steel, or aluminum, which have specific temperature ranges they can withstand. Extreme temperatures, whether hot or cold, can affect the mechanical properties of the coupling material. High temperatures may lead to thermal expansion, which can affect the coupling’s fit and alignment. On the other hand, extremely low temperatures can cause the material to become brittle, reducing its flexibility and impact resistance. It is crucial to choose a universal coupling that is suitable for the anticipated temperature range in the application to ensure reliable performance.

Environmental Conditions: Universal couplings used in harsh environments, such as those exposed to moisture, chemicals, dust, or abrasive particles, need to be made from corrosion-resistant and durable materials. Corrosion can degrade the coupling over time, leading to reduced performance and potential failure. Additionally, environmental contaminants can affect the smooth operation of the coupling and cause premature wear. Proper sealing and protective coatings can enhance the coupling’s resistance to environmental factors.

Dynamic Operating Conditions: Some applications may subject the universal coupling to dynamic loads, shocks, or high-speed rotations. In such cases, the coupling’s fatigue strength and torsional stiffness become critical factors. High dynamic loads and shock forces can lead to stress concentration and fatigue failure in the coupling if it is not appropriately designed for such conditions.

Alignment Maintenance: Temperature variations and environmental conditions can cause changes in the alignment of the connected shafts. It is essential to regularly inspect and maintain the alignment of the coupling to prevent excessive wear and ensure optimal performance.

Overall, selecting a universal coupling that is designed to withstand the specific temperature and environmental conditions of the application is crucial for ensuring its longevity and reliable performance in mechanical systems.

Can Universal Couplings Accommodate Misalignment in Shafts and Drives?

Yes, universal couplings are specifically designed to accommodate misalignment between shafts and drives. The unique design of universal couplings allows them to transmit torque and rotation between two shafts that are not in perfect alignment with each other. There are two primary types of misalignment that universal couplings can handle:

- Angular Misalignment: Universal couplings can handle angular misalignment, which occurs when the shafts are not in line with each other and form an angle. The design of the universal joint allows it to bend and flex at different angles, allowing the shafts to stay connected and transmit torque even when they are not perfectly aligned.

- Parallel Misalignment: Universal couplings can also handle parallel misalignment, which occurs when the two shafts are not perfectly parallel to each other. The flexible nature of the universal joint allows it to compensate for small variations in parallel alignment, ensuring that the shafts remain connected and transmit power efficiently.

By accommodating misalignment, universal couplings help to reduce stress on the shafts and other connected components, thus preventing premature wear and failure. They are commonly used in various applications, including automotive drivetrains, industrial machinery, marine propulsion systems, and aerospace equipment, where misalignment is inevitable due to the dynamic nature of the systems.

editor by CX 2023-08-16

China Best Quality Round Shape Metal Brake Drum Gear Couplings for Drum Couplings Available at Best Price for Export coupling distance

Guarantee: 1 12 months

Relevant Industries: Other, Devices and Autos

Personalized support: OEM

Composition: Common

Versatile or Rigid: Versatile

Common or Nonstandard: Regular

Substance: Metallic, Metal

Item Name: Brake Drum Gear Coupling

Variety: Brake Drum Equipment Coupling

Spherical: Round

Packaging Particulars: Wooden or curton

Port: Mumbai Bangalore Ahmedabad Delhi

Our firm has acquired a remarkable market in the sector by providing a premium top quality Brake Drum Gear Couplings. Broadly employed in a variety of industries this kind of steel, engineering, textile, petrochemical, car, etc., these are hugely acknowledged for their non-abrasive character, large longevity, and minimal servicing. These are manufactured by making use of the ideal quality uncooked resources and innovative methods. Moreover, these couplings can also be availed by our clients, at the most affordable charges. Specification

| item | value |

| Product Title | Brake Drum Equipment Couplings |

| Brand Identify | Aira Trex |

| Type | Brake Drum Gear Couplings |

| Business Type | Exporter, Provider |

| Material | Metal |

| Shape | Round |

| Use | Drum Couplings |

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by czh 2023-02-19

China manufacturer & factory supplier for wpa in Rome Italy gear box 20hp 3000 rpm high torque 3 phase motor gearbox with worm gear motor speed reducer small engine gear box With high quality best price & service

EPT chains, the two common and non-normal, are produced of: ○ Large quality steels: dimensions and adapted chemical composition for the diverse chain areas ○ The most productive manufacturing procedures: • Particular technique for the creation of bushes improving the chain use resistance ( EPT know-how) • Plates created by multi-stage processing instruments ensuring a regular pitch ( EPT technology) ○ Satisfactory mechanical and heat remedies of chain elements: • Shot peening • Surface area finishing • Scenario hardening, carbonitriding, quenching, tempering … • EPT®treatment • Freezing therapy • Corrosion security coatings (GEOMET, zinc, nickel plating, …) In the meantime, our items are created according to higher good quality standards, and complying with the international superior standard conditions.

Overview

Rapid Information

- Applicable Industries:

-

Building Materials Retailers

- Gearing Arrangement:

-

Worm

- Output Torque:

-

up to 5000Nm

- Input Pace:

-

750rpm -2000rpm

- OutputGirard DYN variety-2 Our assortment of worm gearboxes is especially suited to demanding stepper and servo motor purposes. Speed:

-

10-500rpm

- Spot of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Colour:

-

Customer Ask for

- Housing Material:

-

Solid Iron

- Shaft:

-

Inline

- Heat remedy:

-

Quenching

- Bearing material:

-

SKF,ZWZ

Source Potential

- Supply Capability:

- 20000 Piece/Parts for each Thirty day period

Packaging & Delivery

- Packaging Details

- Standard export Packing(Carton Blanket+ picket box)

- Port

- Ningbo or Shanghai

-

Lead Time

: -

The PTO shaft is the mechanical device that transfer the electricity from the tractor to the agricultural implement. The PTO shaft is manufactured of two joints linked by telescopic tubes: a single joint connects the outer tube of the PTO shaft with the tractor electrical power just take-off , the other joint connects the inner tube of the PTO shaft with the put into action. The range of the EPG Team PTO shafts involves 9 measurements of various dimensions in accordance to the electricity to be transferred . The dimensions of the EPG Team PTO shafts and the power that can be transferred at 540 rpm are : Dimensions 1 up to 16HP Dimensions 2 up to 21HP Dimensions 3 up to thirty HP Measurement 4 up to 35HP Size 5 up to 47HP Dimension 6 up to 60HP Measurement 7 up to 70HP Measurement 8 up to 90HP SIZE10 up to 110HP

Adhering to “Survival by Top quality, Improvement by Technological innovation & Credit history”, The organization will continually enhance merchandise overall performance to meet up with the escalating buyer specifications in the demanding style of operate.

Amount(Boxes) 1 – one thousand >1000 Est. Time(times) twenty five To be negotiated

On the web Customization

Item Description

WP stepper motor worm equipment/worm gear velocity reducer/AC worm gearbox

1.Broadly utilised in gentle sector, very good resistance to donning, with large precision in proportions, lower noise, advanced centric

working castings

two. The housing is of strong hardness, compact framework

three. Stable transmission, lower vibration, large ratio, canbe matched with different machines

one.Housing:iron forged

two. reduced sound(<50DB)

three.Product:WPA forty-250,Ratio:ten to sixty

four.Effective and safe functioning

five.ISO9001,Manufacturing facility price tag,OEM

six.Technology Knowledge:

|

Type: |

gearbox WPA |

||||||

|

Product: |

WPA 40-250 |

||||||

|

Ratio: |

1:ten,fifteen,twenty,twenty five,thirty,40,fifty,sixty |

||||||

|

Coloration: |

Blue/Silver Or On Client Ask for |

||||||

|

Material: |

Housing: Die-Cast Iron cast Worm Equipment-Copper-ten-3# Worm-20CrMn Ti with carburizing and quenching, area harness is fifty six-62HRC |

||||||

|

Packing: |

Carton and Wood Scenario |

||||||

|

Bearing: |

C&U Bearing |

||||||

|

Warranty: |

1 Calendar year |

||||||

Company Profile

FAQ

Q: Are you investing firm or producer ?

A: Our team consists in 3 factories and 2 abroad income businesses.

Q: Do you offer samples ? is it totally free or extra ?

A: Sure, we could offer you the sample for cost-free charge but do not pay the price of freight.

Q:How prolonged is your supply time ? What is your terms of payment ?

A: Generally it is forty-forty five days. The time could fluctuate based on the product and the amount of customization. For common merchandise, the payment is: 30% T/T in advance ,equilibrium before shippment.

Q:What is the actual MOQ or cost for your item ?

A: As an OEM business, we can provide and adapt our items to a vast assortment of wants.Therefore, MOQ and price tag may possibly tremendously range with measurement, material and additional specs For instance, expensive products or normal products will typically have a lower MOQ. Please speak to us with all pertinent particulars to get the most exact quotation.

If you have another query, please truly feel free of charge to make contact with us.

Why Pick Us

Also I would like to get this prospect to give a brief introduction of our At any time-Electricity firm: Our organization is a well-known

manufacturer of agriculture gearbox,worm lessen gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in

china. We have exported a lot of merchandise to our consumers all above the globe, we have long-time experience and powerful technologies

help. Some of our buyer : Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini Germany: SILOKING ,GKN ,KTS France: Itfran,

Sedies, Kuhn Brazil: AEMCO ,STU United states of america: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS Canada: JAY-LOR , CANIMEX ,RingBall

…… -> Our Organization with more than twelve year’s historical past and a thousand personnel and 20 product sales. -> With over 100 Million USD sales in 2017 ->

With progress machinery equipments -> With large work capacity and high high quality manage, ISO certified. …… you also can check out

our website to know for much more information, if you want our merchandise catalogue, you should contact with us.

Speak to Us

|

FOR More Depth, Please Contact US. |

||

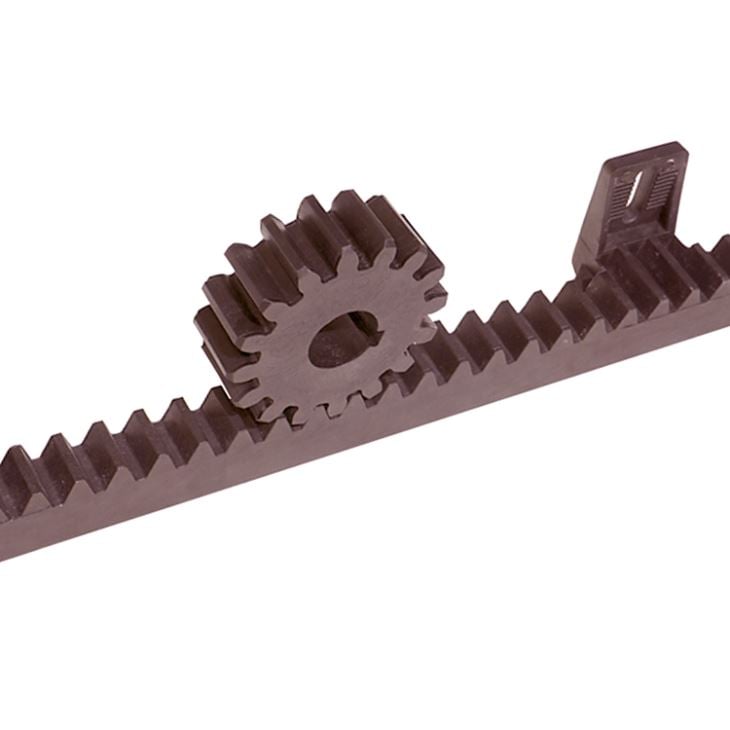

China manufacturer & factory supplier for China in West Yorkshire United Kingdom manufacturer China Factory Large Diameter Plastic Spur Gear With high quality best price & service

As a outcome, we have grow to be a thorough maker in the movement and manage field delivering an in depth lineup of products with excellent longevity, environment-friendliness, and high quality.We also can design and make non-regular goods to fulfill customers’ special needs.

Overview

Quick Particulars

- Applicable Industries:

-

Creating Materials Outlets, Production Plant, Machinery Mend Retailers, Foodstuff & Beverage Factory, Farms, Construction works , Energy & Mining, agricultural machiner

- Solution title:

-

China Manufacturing unit Big Diameter Plastic Spur Gear

- Application:

-

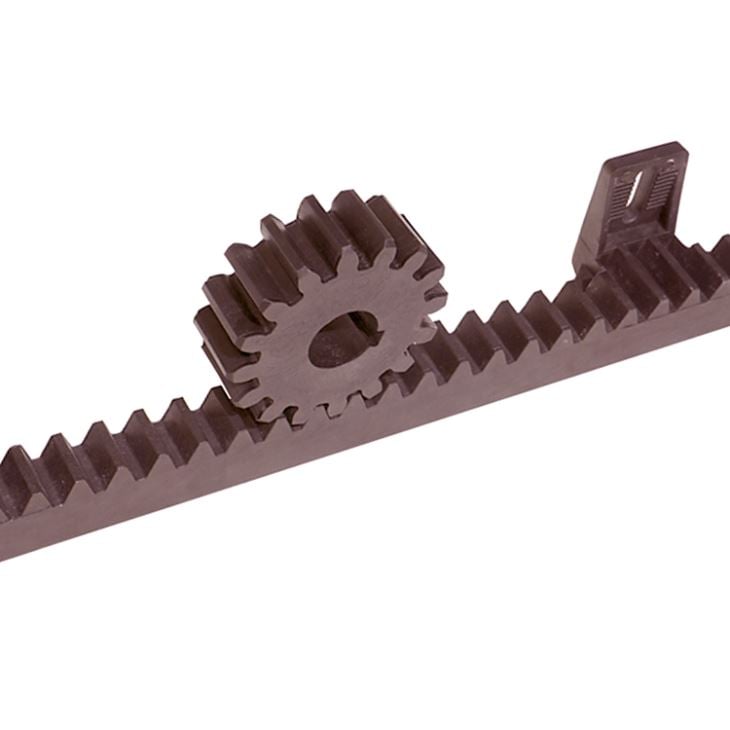

Match with the equipment rack

- Processing:

-

Hobbing

- Colour:

-

Normal or black

If undistributed hundreds or continued start off-ups are foreseen, it is advisable to insert compensating couplings, connectors, torque limiters and so forth.

- Stress Angle:

-

20 Degree

- Precision:

-

DIN6/7/8/9/ten

- Sort:

-

Straight enamel

Shear bolt torque limiter (SB) EPG Team offers substantial quality PTO shafts with tubes set by spring pin, cross joints with roller bearings with rollers

- Hub:

-

With hub or with no hub

- Tooth:

-

10T-100T

- MOQ:

-

5pcs

Supply Capability

- Source Potential:

- 5000 Piece/Pieces for each Month

Packaging & Supply

- Packaging Information

- Carton ,Wood situation or as your want

- Port

- Tianjin/Qingdao/Shanghai Port

-

Lead Time

: -

Amount(Baggage) 1 – 50 Our company is situated in XiHu HangZhou Zhejiang Province. T

fifty one – 100 >100 Est. Time(times) fifteen 25 To be negotiated

On the internet Customization

Specification

|

China Manufacturing facility Large Diameter Plastic Spur Equipment |

|

|

Module: |

M0.5-M10 |

|

Content: |

Plastic/POM/Nylon |

|

Stress angle: |

20 degree |

|

Precision grade: |

DIN6/DIN7/DIN8/DIN9/DIN10 |

|

Machining approach: |

Hobbing, Milling, Drilling, Shaving, Grinding |

|

Warmth remedy: |

Hardening and Tempering, Large Frequency Quenching,Carburizing and many others |

|

Surface area treatment: |

Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

Item Display

Our Helical Gear

Distinct Coloration Gears

Procedure

Packing

Usuallu used the suitable for transportation by sea, rail, air, and other ideal for import and export customs clearance of free fumigation wooden box of free of charge fumigation wood pallets (precision goods utilised the collision coating layer in the packaging box, to make certain the goods risk-free sufficient).

Remarks:

All items are checked and examined totally throughout every functioning method, and soon after the item is ultimately made to guarantee that the greatest high quality product enter into the market.

Payment & Shipping and delivery

Our Other Goods

Spur gear

Bevel gear

Gear rack

Sprocket

Timing pulley

Timing belt

Roller chain

Worm gear & shaft

Linear rail & block

Get in touch with Us

Best China manufacturer & factory factory in Karaj Iran manufacturer for High quality helical bevel gear pinion With high quality best price

The high quality of products is for us and for our clients of high importance. This is why we use European manufactured factors in our items. We also execute continual management of incoming components and the control of finished goods. In our business we function according to ISO 9001. If you are interested in any of our goods or would like to examine a potential get, you should truly feel free of charge to get in touch with us.

Overview

Rapid Particulars

- Relevant Industries:

-

Producing Plant

- Merchandise Key phrases:

-

Precision Worm Gearboxes and Worm-Wheel Sets

helical bevel gear,good quality pinion gear,high quality gear

Source Potential

- Source Ability:

- 5000 Piece/Pieces per Month

Packaging & Shipping and delivery

- Packaging Information

- Neutral paper packaging, picket packing containers for outer box or in accordance to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

On the internet Customization

We At any time-Electrical power Team with 4 branches above 1200 personnel is one of the largest transmission components and machining items producers in China

Underneath the assistance of managerial perception of “Serving agriculture, scoring a achievement by means of quality of goods and honesty in company”, our goods have been dependable by clientele and have received a more substantial share of market place.

Underneath the assistance of managerial perception of “Serving agriculture, scoring a achievement by means of quality of goods and honesty in company”, our goods have been dependable by clientele and have received a more substantial share of market place.

Merchandise Description

Merchandise Description:

We specialised in manufacturing car gears , bike gears, gearbox, specific automobile (power takeoff, snowmobiles, engineering autos) gears, generator components, stainless steel ice crusher and so on.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Approach |

Equipment Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1., 1.twenty five, 1.5, 1.seventy five, 2., 2.25, 2.5….8. and so on. |

|

Warmth Therapy |

Carburizing & Quenching, Carbonitriding |

|

Normal |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Best China manufacturer & factory factory in Bogota Colombia manufacturer for High quality miniature gears gear bevel With high quality best price

Meanwhile, our products are manufactured according to hOur factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China. igh quality standards, and complying with the international advanced standard criteria.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product Keywords:

-

miniature gears,miniature gear,miniature bevel gear

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

Online Customization

To address these sealing and efficiency issues, Emerson Power Transmission (EPT) developed several design and manufacturing recommendations. The resulting gearboxes tend to run cooler and leak free, compared with conventional worm gear units.

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

Product Description:

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

The EPG GROUP range of PTO shafts accessories includes various types of yokes for the connection of the tractor power take-off with recessed push button and/or ball collar and/or ball collar for constant velocity joints, with the following spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20

The EPG GROUP range of PTO shafts accessories includes various types of yokes for the connection of the tractor power take-off with recessed push button and/or ball collar and/or ball collar for constant velocity joints, with the following spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20