Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Signs of Wear or Failure in a Universal Coupling

Universal couplings are critical components in power transmission systems, and detecting signs of wear or impending failure is crucial to prevent equipment damage and ensure safe operation. Here are some common signs to look out for:

- Abnormal Noise: Unusual noises, such as clicking, grinding, or squeaking, during equipment operation can indicate misalignment, wear, or damaged universal coupling components.

- Vibration: Excessive vibration in the machinery may suggest misalignment or imbalance in the universal coupling or connected components.

- Visible Wear: Inspect the universal coupling visually for signs of wear, such as deformation, cracks, or visible damage to the coupling elements or shaft connections.

- Looseness: Check for any looseness in the universal coupling, shaft connections, or locking mechanisms. Loose components can lead to misalignment and accelerated wear.

- Shaft Movement: If there is axial or radial movement in the shafts during operation, it may indicate worn or damaged universal coupling components.

- Increased Operating Temperature: A rise in operating temperature beyond normal levels could be a result of friction and misalignment in the universal coupling.

- Reduced Performance: If the equipment’s performance declines, such as reduced power transmission efficiency or speed fluctuations, it may be a sign of coupling wear or failure.

- Grease Leakage: In grease-lubricated universal couplings, excessive grease leakage around the coupling seals can be an indication of seal damage or wear.

- Frequent Maintenance Issues: If the machinery equipped with a universal coupling requires frequent maintenance or repairs, it may be due to coupling issues that need attention.

- Age and Service Life: Consider the age of the universal coupling and its service life. Over time, couplings experience wear and fatigue, and older couplings may require closer inspection.

If any of these signs are observed, it is essential to take immediate action. Discontinue equipment operation, inspect the universal coupling thoroughly, and consult a qualified professional to determine the cause and plan necessary repairs or replacement. Regular maintenance and inspection can help detect potential issues early, ensuring the safe and efficient operation of the mechanical system.

How do you calculate the required size and specifications for a half coupling?

Calculating the required size and specifications for a half coupling involves considering several factors to ensure a proper fit and secure connection. Here are the steps to calculate the required size and specifications:

1. Pipe Size: Determine the size of the pipe that the half coupling will connect to. Pipe sizes are typically specified in inches, and the half coupling size should match the pipe size.

2. Pipe Material: Identify the material of the pipe, such as stainless steel, PVC, carbon steel, brass, copper, etc. The half coupling material should be compatible with the pipe material to prevent corrosion and ensure a reliable connection.

3. Pressure Rating: Determine the maximum operating pressure of the system. The half coupling should have a pressure rating that meets or exceeds the system’s operating pressure to ensure safety and performance.

4. Temperature Rating: Consider the maximum and minimum operating temperatures of the system. The half coupling material and design should be suitable for the temperature range to prevent deformation or failure.

5. Alignment and Misalignment: Evaluate the alignment and potential misalignment between the pipes. Some half couplings are designed to accommodate angular, parallel, or axial misalignment, providing flexibility in installation.

6. End Connection: Determine the type of end connection required for the half coupling, such as threaded, weld-on, or flanged. The end connection should match the corresponding connection on the pipe.

7. Corrosion Resistance: Consider the environment in which the half coupling will be installed. For corrosive environments, select a half coupling material with suitable corrosion resistance.

8. Industry Standards: Ensure that the selected half coupling complies with relevant industry standards and certifications for quality and safety.

9. Manufacturer Guidelines: Follow the manufacturer’s guidelines and recommendations for selecting the appropriate half coupling size and specifications based on the application requirements.

It is essential to consult with coupling manufacturers, suppliers, or industry experts if you are unsure about the correct size and specifications for the half coupling. Proper sizing and selection will ensure a reliable and efficient connection in the piping system.

Advantages of Using a Universal Coupling in a Drive System

A universal coupling, also known as a universal joint or U-joint, offers several advantages when used in a drive system:

- Flexibility: Universal couplings can transmit torque and rotation between shafts that are not in a straight line and have angular misalignment. This flexibility allows for easier design and installation of the drive system, especially in applications where the shafts are not perfectly aligned.

- Angular Misalignment Compensation: The universal joint can handle angular misalignment between the connected shafts, making it suitable for applications where the shafts are at different angles to each other. This feature helps reduce stress on the shafts and bearings, leading to extended component life.

- Smooth Power Transmission: The double universal joint, also known as the double Cardan joint, can reduce the angular variation between the input and output shafts, resulting in smoother power transmission and reduced vibration in certain applications.

- Constant Velocity: The constant velocity joint (CV joint) maintains a constant velocity ratio between the input and output shafts. This is particularly important in automotive drive shafts, especially in front-wheel-drive vehicles, where the drive shafts must adjust to changing angles as the wheels turn. The constant velocity feature provides a smoother ride and reduces vibration.

- Compact Design: Universal couplings have a relatively simple design, which allows for a compact and lightweight construction. This is advantageous in applications where space and weight are critical factors.

- Cost-Effective: Universal couplings are cost-effective compared to some other types of couplings, making them a popular choice for various mechanical systems.

- Reliability: When properly lubricated and maintained, universal couplings can provide reliable and efficient power transmission for a long service life.

- Versatility: Universal couplings are versatile and find applications in various industries, including automotive, aerospace, marine, industrial machinery, and power transmission systems.

In conclusion, the universal coupling’s ability to handle misalignment and provide flexibility in power transmission makes it a valuable component in many drive systems. Its advantages in compensating for angular misalignment, ensuring smooth power transmission, and offering a cost-effective and reliable solution have contributed to its widespread use in different mechanical applications.

editor by CX 2024-05-02

China wholesaler Densen customized GIICL7 type gear couplings,gear tooth couplings,industrial gear couplings with high quality

Warranty: 3 a long time

Applicable Industries: Garment Outlets, Developing Substance Shops, Manufacturing Plant, Equipment Repair Shops, Farms, Construction works , Vitality & Mining, metallurgy/engineering

Custom-made help: OEM

Structure: Equipment

Versatile or Rigid: Versatile

Common or Nonstandard: Common

Materials: Steel

Coloration: Tailored

Certification: iso ce

Packaging Specifics: Wood cage or regular exporting package deal

Port: HangZhou or other major ports in China

Densen personalized GIICL7 variety gear couplings,equipment tooth couplings,industrial equipment couplings

| Product Identify | Densen custom-made GIICL7 kind gear couplings,gear tooth couplings,industrial gear couplings |

| DN mm | sixteen-1040mm |

| Rated Torque | .4~4500 kN·m |

| Allowalbe Speed | 4000~460RPM |

| Material | 45# Steel or 42CrMo |

| Application | Broadly used in metallurgy, mining, engineering and other fields. |

Products display:

Organization Info

Tools

Software CaseTypical circumstance of diaphragm coupling used to variable frequency speed control equipment

JMB variety coupling is utilized to HangZhou Oilfield Thermal Electrical power Plant

In accordance to the needs of HangZhou Electric powered Electricity Company, HangZhou Oilfield Thermal Power Plant ought to dynamically adjust the power era in accordance to the load of the energy grid and industry demand from customers, and carry out the transformation of the frequency converter and the suction enthusiast. The motor was initially a 1600KW, 730RPM non-frequency variable pace motor matched by HangZhou Motor Factory. The speed management method following shifting the frequency is manual handle. Press the button pace to boost 10RPM or fall 10RPM. The coupling is nevertheless the original elastic decoupling coupling, and the elastic de-coupling coupling soon after frequency conversion is regularly destroyed, which directly influences the normal energy generation.

It is identified by means of analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation approach (the diameter of the admirer impeller is 3.3 meters) and is lower off, which has excellent damage to the motor and the enthusiast.

Later, they switched to the JMB460 double-diaphragm wheel-kind coupling of our factory (patent quantity: ZL.99246247.9). Following 1 hour of damaging experiment and a lot more than 1 yr of procedure check, the products is operating really well, and there is no Substitute the diaphragm. 12 models have been rebuilt and the procedure is in very good issue.

Other Software Case

Packaging & Shipping and delivery

Contact us

How to Choose the Right Worm Shaft

You might be curious to know how to choose the right Worm Shaft. In this article, you will learn about worm modules with the same pitch diameter, Double-thread worm gears, and Self-locking worm drive. Once you have chosen the proper Worm Shaft, you will find it easier to use the equipment in your home. There are many advantages to selecting the right Worm Shaft. Read on to learn more.

Concave shape

The concave shape of a worm’s shaft is an important characteristic for the design of a worm gearing. Worm gearings can be found in a wide range of shapes, and the basic profile parameters are available in professional and firm literature. These parameters are used in geometry calculations, and a selection of the right worm gearing for a particular application can be based on these requirements.

The thread profile of a worm is defined by the tangent to the axis of its main cylinder. The teeth are shaped in a straight line with a slightly concave shape along the sides. It resembles a helical gear, and the profile of the worm itself is straight. This type of gearing is often used when the number of teeth is greater than a certain limit.

The geometry of a worm gear depends on the type and manufacturer. In the earliest days, worms were made similar to simple screw threads, and could be chased on a lathe. During this time, the worm was often made with straight-sided tools to produce threads in the acme plane. Later, grinding techniques improved the thread finish and reduced distortions resulting from hardening.

When a worm gearing has multiple teeth, the pitch angle is a key parameter. A greater pitch angle increases efficiency. If you want to increase the pitch angle without increasing the number of teeth, you can replace a worm pair with a different number of thread starts. The helix angle must increase while the center distance remains constant. A higher pitch angle, however, is almost never used for power transmissions.

The minimum number of gear teeth depends on the angle of pressure at zero gearing correction. The diameter of the worm is d1, and is based on a known module value, mx or mn. Generally, larger values of m are assigned to larger modules. And a smaller number of teeth is called a low pitch angle. In case of a low pitch angle, spiral gearing is used. The pitch angle of the worm gear is smaller than 10 degrees.

Multiple-thread worms

Multi-thread worms can be divided into sets of one, two, or four threads. The ratio is determined by the number of threads on each set and the number of teeth on the apparatus. The most common worm thread counts are 1,2,4, and 6. To find out how many threads you have, count the start and end of each thread and divide by two. Using this method, you will get the correct thread count every time.

The tangent plane of a worm’s pitch profile changes as the worm moves lengthwise along the thread. The lead angle is greatest at the throat, and decreases on both sides. The curvature radius r” varies proportionally with the worm’s radius, or pitch angle at the considered point. Hence, the worm leads angle, r, is increased with decreased inclination and decreases with increasing inclination.

Multi-thread worms are characterized by a constant leverage between the gear surface and the worm threads. The ratio of worm-tooth surfaces to the worm’s length varies, which enables the wormgear to be adjusted in the same direction. To optimize the gear contact between the worm and gear, the tangent relationship between the two surfaces is optimal.

The efficiency of worm gear drives is largely dependent on the helix angle of the worm. Multiple thread worms can improve the efficiency of the worm gear drive by as much as 25 to 50% compared to single-thread worms. Worm gears are made of bronze, which reduces friction and heat on the worm’s teeth. A specialized machine can cut the worm gears for maximum efficiency.

Double-thread worm gears

In many different applications, worm gears are used to drive a worm wheel. These gears are unique in that the worm cannot be reversed by the power applied to the worm wheel. Because of their self-locking properties, they can be used to prevent reversing motion, although this is not a dependable function. Applications for worm gears include hoisting equipment, elevators, chain blocks, fishing reels, and automotive power steering. Because of their compact size, these gears are often used in applications with limited space.

Worm sets typically exhibit more wear than other types of gears, and this means that they require more limited contact patterns in new parts. Worm wheel teeth are concave, making it difficult to measure tooth thickness with pins, balls, and gear tooth calipers. To measure tooth thickness, however, you can measure backlash, a measurement of the spacing between teeth in a gear. Backlash can vary from one worm gear to another, so it is important to check the backlash at several points. If the backlash is different in two places, this indicates that the teeth may have different spacing.

Single-thread worm gears provide high speed reduction but lower efficiency. A multi-thread worm gear can provide high efficiency and high speed, but this comes with a trade-off in terms of horsepower. However, there are many other applications for worm gears. In addition to heavy-duty applications, they are often used in light-duty gearboxes for a variety of functions. When used in conjunction with double-thread worms, they allow for a substantial speed reduction in one step.

Stainless-steel worm gears can be used in damp environments. The worm gear is not susceptible to rust and is ideal for wet and damp environments. The worm wheel’s smooth surfaces make cleaning them easy. However, they do require lubricants. The most common lubricant for worm gears is mineral oil. This lubricant is designed to protect the worm drive.

Self-locking worm drive

A self-locking worm drive prevents the platform from moving backward when the motor stops. A dynamic self-locking worm drive is also possible but does not include a holding brake. This type of self-locking worm drive is not susceptible to vibrations, but may rattle if released. In addition, it may require an additional brake to keep the platform from moving. A positive brake may be necessary for safety.

A self-locking worm drive does not allow for the interchangeability of the driven and driving gears. This is unlike spur gear trains that allow both to interchange positions. In a self-locking worm drive, the driving gear is always engaged and the driven gear remains stationary. The drive mechanism locks automatically when the worm is operated in the wrong manner. Several sources of information on self-locking worm gears include the Machinery’s Handbook.

A self-locking worm drive is not difficult to build and has a great mechanical advantage. In fact, the output of a self-locking worm drive cannot be backdriven by the input shaft. DIYers can build a self-locking worm drive by modifying threaded rods and off-the-shelf gears. However, it is easier to make a ratchet and pawl mechanism, and is significantly less expensive. However, it is important to understand that you can only drive one worm at a time.

Another advantage of a self-locking worm drive is the fact that it is not possible to interchange the input and output shafts. This is a major benefit of using such a mechanism, as you can achieve high gear reduction without increasing the size of the gear box. If you’re thinking about buying a self-locking worm gear for a specific application, consider the following tips to make the right choice.

An enveloping worm gear set is best for applications requiring high accuracy and efficiency, and minimum backlash. Its teeth are shaped differently, and the worm’s threads are modified to increase surface contact. They are more expensive to manufacture than their single-start counterparts, but this type is best for applications where accuracy is crucial. The worm drive is also a great option for heavy trucks because of their large size and high-torque capacity.

editor by czh

China manufacturer & factory supplier for wpa in Rome Italy gear box 20hp 3000 rpm high torque 3 phase motor gearbox with worm gear motor speed reducer small engine gear box With high quality best price & service

EPT chains, the two common and non-normal, are produced of: ○ Large quality steels: dimensions and adapted chemical composition for the diverse chain areas ○ The most productive manufacturing procedures: • Particular technique for the creation of bushes improving the chain use resistance ( EPT know-how) • Plates created by multi-stage processing instruments ensuring a regular pitch ( EPT technology) ○ Satisfactory mechanical and heat remedies of chain elements: • Shot peening • Surface area finishing • Scenario hardening, carbonitriding, quenching, tempering … • EPT®treatment • Freezing therapy • Corrosion security coatings (GEOMET, zinc, nickel plating, …) In the meantime, our items are created according to higher good quality standards, and complying with the international superior standard conditions.

Overview

Rapid Information

- Applicable Industries:

-

Building Materials Retailers

- Gearing Arrangement:

-

Worm

- Output Torque:

-

up to 5000Nm

- Input Pace:

-

750rpm -2000rpm

- OutputGirard DYN variety-2 Our assortment of worm gearboxes is especially suited to demanding stepper and servo motor purposes. Speed:

-

10-500rpm

- Spot of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Colour:

-

Customer Ask for

- Housing Material:

-

Solid Iron

- Shaft:

-

Inline

- Heat remedy:

-

Quenching

- Bearing material:

-

SKF,ZWZ

Source Potential

- Supply Capability:

- 20000 Piece/Parts for each Thirty day period

Packaging & Delivery

- Packaging Details

- Standard export Packing(Carton Blanket+ picket box)

- Port

- Ningbo or Shanghai

-

Lead Time

: -

The PTO shaft is the mechanical device that transfer the electricity from the tractor to the agricultural implement. The PTO shaft is manufactured of two joints linked by telescopic tubes: a single joint connects the outer tube of the PTO shaft with the tractor electrical power just take-off , the other joint connects the inner tube of the PTO shaft with the put into action. The range of the EPG Team PTO shafts involves 9 measurements of various dimensions in accordance to the electricity to be transferred . The dimensions of the EPG Team PTO shafts and the power that can be transferred at 540 rpm are : Dimensions 1 up to 16HP Dimensions 2 up to 21HP Dimensions 3 up to thirty HP Measurement 4 up to 35HP Size 5 up to 47HP Dimension 6 up to 60HP Measurement 7 up to 70HP Measurement 8 up to 90HP SIZE10 up to 110HP

Adhering to “Survival by Top quality, Improvement by Technological innovation & Credit history”, The organization will continually enhance merchandise overall performance to meet up with the escalating buyer specifications in the demanding style of operate.

Amount(Boxes) 1 – one thousand >1000 Est. Time(times) twenty five To be negotiated

On the web Customization

Item Description

WP stepper motor worm equipment/worm gear velocity reducer/AC worm gearbox

1.Broadly utilised in gentle sector, very good resistance to donning, with large precision in proportions, lower noise, advanced centric

working castings

two. The housing is of strong hardness, compact framework

three. Stable transmission, lower vibration, large ratio, canbe matched with different machines

one.Housing:iron forged

two. reduced sound(<50DB)

three.Product:WPA forty-250,Ratio:ten to sixty

four.Effective and safe functioning

five.ISO9001,Manufacturing facility price tag,OEM

six.Technology Knowledge:

|

Type: |

gearbox WPA |

||||||

|

Product: |

WPA 40-250 |

||||||

|

Ratio: |

1:ten,fifteen,twenty,twenty five,thirty,40,fifty,sixty |

||||||

|

Coloration: |

Blue/Silver Or On Client Ask for |

||||||

|

Material: |

Housing: Die-Cast Iron cast Worm Equipment-Copper-ten-3# Worm-20CrMn Ti with carburizing and quenching, area harness is fifty six-62HRC |

||||||

|

Packing: |

Carton and Wood Scenario |

||||||

|

Bearing: |

C&U Bearing |

||||||

|

Warranty: |

1 Calendar year |

||||||

Company Profile

FAQ

Q: Are you investing firm or producer ?

A: Our team consists in 3 factories and 2 abroad income businesses.

Q: Do you offer samples ? is it totally free or extra ?

A: Sure, we could offer you the sample for cost-free charge but do not pay the price of freight.

Q:How prolonged is your supply time ? What is your terms of payment ?

A: Generally it is forty-forty five days. The time could fluctuate based on the product and the amount of customization. For common merchandise, the payment is: 30% T/T in advance ,equilibrium before shippment.

Q:What is the actual MOQ or cost for your item ?

A: As an OEM business, we can provide and adapt our items to a vast assortment of wants.Therefore, MOQ and price tag may possibly tremendously range with measurement, material and additional specs For instance, expensive products or normal products will typically have a lower MOQ. Please speak to us with all pertinent particulars to get the most exact quotation.

If you have another query, please truly feel free of charge to make contact with us.

Why Pick Us

Also I would like to get this prospect to give a brief introduction of our At any time-Electricity firm: Our organization is a well-known

manufacturer of agriculture gearbox,worm lessen gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in

china. We have exported a lot of merchandise to our consumers all above the globe, we have long-time experience and powerful technologies

help. Some of our buyer : Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini Germany: SILOKING ,GKN ,KTS France: Itfran,

Sedies, Kuhn Brazil: AEMCO ,STU United states of america: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS Canada: JAY-LOR , CANIMEX ,RingBall

…… -> Our Organization with more than twelve year’s historical past and a thousand personnel and 20 product sales. -> With over 100 Million USD sales in 2017 ->

With progress machinery equipments -> With large work capacity and high high quality manage, ISO certified. …… you also can check out

our website to know for much more information, if you want our merchandise catalogue, you should contact with us.

Speak to Us

|

FOR More Depth, Please Contact US. |

||

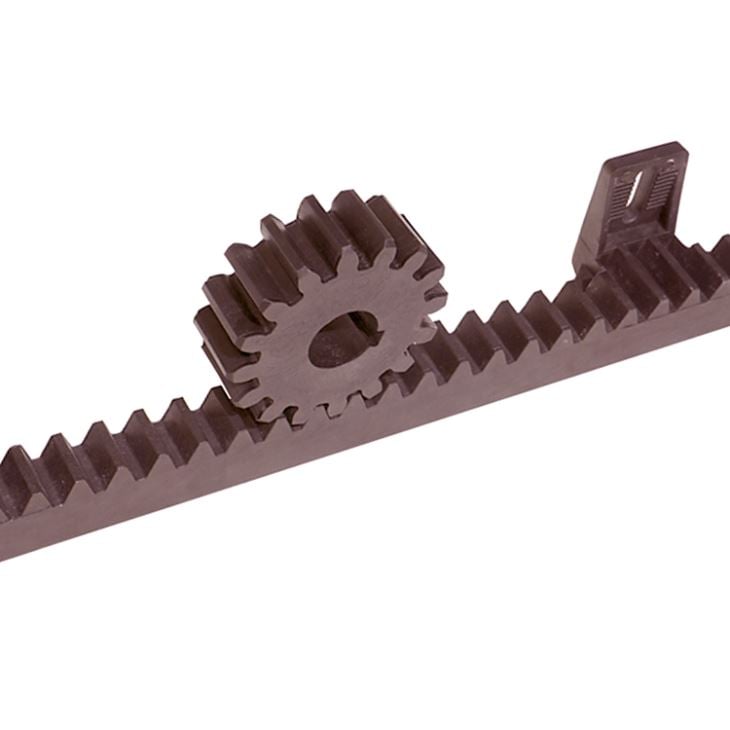

China manufacturer & factory supplier for China in West Yorkshire United Kingdom manufacturer China Factory Large Diameter Plastic Spur Gear With high quality best price & service

As a outcome, we have grow to be a thorough maker in the movement and manage field delivering an in depth lineup of products with excellent longevity, environment-friendliness, and high quality.We also can design and make non-regular goods to fulfill customers’ special needs.

Overview

Quick Particulars

- Applicable Industries:

-

Creating Materials Outlets, Production Plant, Machinery Mend Retailers, Foodstuff & Beverage Factory, Farms, Construction works , Energy & Mining, agricultural machiner

- Solution title:

-

China Manufacturing unit Big Diameter Plastic Spur Gear

- Application:

-

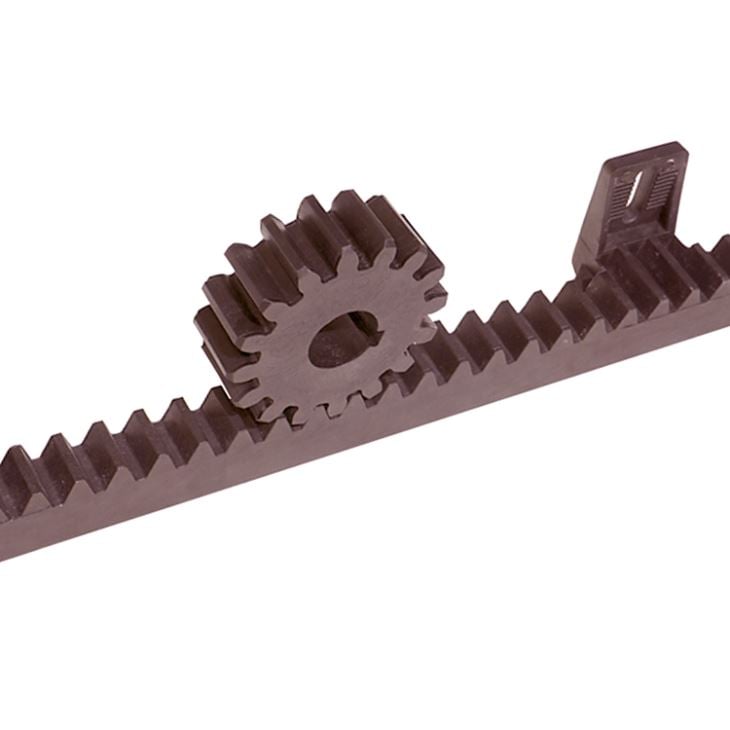

Match with the equipment rack

- Processing:

-

Hobbing

- Colour:

-

Normal or black

If undistributed hundreds or continued start off-ups are foreseen, it is advisable to insert compensating couplings, connectors, torque limiters and so forth.

- Stress Angle:

-

20 Degree

- Precision:

-

DIN6/7/8/9/ten

- Sort:

-

Straight enamel

Shear bolt torque limiter (SB) EPG Team offers substantial quality PTO shafts with tubes set by spring pin, cross joints with roller bearings with rollers

- Hub:

-

With hub or with no hub

- Tooth:

-

10T-100T

- MOQ:

-

5pcs

Supply Capability

- Source Potential:

- 5000 Piece/Pieces for each Month

Packaging & Supply

- Packaging Information

- Carton ,Wood situation or as your want

- Port

- Tianjin/Qingdao/Shanghai Port

-

Lead Time

: -

Amount(Baggage) 1 – 50 Our company is situated in XiHu HangZhou Zhejiang Province. T

fifty one – 100 >100 Est. Time(times) fifteen 25 To be negotiated

On the internet Customization

Specification

|

China Manufacturing facility Large Diameter Plastic Spur Equipment |

|

|

Module: |

M0.5-M10 |

|

Content: |

Plastic/POM/Nylon |

|

Stress angle: |

20 degree |

|

Precision grade: |

DIN6/DIN7/DIN8/DIN9/DIN10 |

|

Machining approach: |

Hobbing, Milling, Drilling, Shaving, Grinding |

|

Warmth remedy: |

Hardening and Tempering, Large Frequency Quenching,Carburizing and many others |

|

Surface area treatment: |

Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

Item Display

Our Helical Gear

Distinct Coloration Gears

Procedure

Packing

Usuallu used the suitable for transportation by sea, rail, air, and other ideal for import and export customs clearance of free fumigation wooden box of free of charge fumigation wood pallets (precision goods utilised the collision coating layer in the packaging box, to make certain the goods risk-free sufficient).

Remarks:

All items are checked and examined totally throughout every functioning method, and soon after the item is ultimately made to guarantee that the greatest high quality product enter into the market.

Payment & Shipping and delivery

Our Other Goods

Spur gear

Bevel gear

Gear rack

Sprocket

Timing pulley

Timing belt

Roller chain

Worm gear & shaft

Linear rail & block

Get in touch with Us

Best China manufacturer & factory factory in Karaj Iran manufacturer for High quality helical bevel gear pinion With high quality best price

The high quality of products is for us and for our clients of high importance. This is why we use European manufactured factors in our items. We also execute continual management of incoming components and the control of finished goods. In our business we function according to ISO 9001. If you are interested in any of our goods or would like to examine a potential get, you should truly feel free of charge to get in touch with us.

Overview

Rapid Particulars

- Relevant Industries:

-

Producing Plant

- Merchandise Key phrases:

-

Precision Worm Gearboxes and Worm-Wheel Sets

helical bevel gear,good quality pinion gear,high quality gear

Source Potential

- Source Ability:

- 5000 Piece/Pieces per Month

Packaging & Shipping and delivery

- Packaging Information

- Neutral paper packaging, picket packing containers for outer box or in accordance to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

On the internet Customization

We At any time-Electrical power Team with 4 branches above 1200 personnel is one of the largest transmission components and machining items producers in China

Underneath the assistance of managerial perception of “Serving agriculture, scoring a achievement by means of quality of goods and honesty in company”, our goods have been dependable by clientele and have received a more substantial share of market place.

Underneath the assistance of managerial perception of “Serving agriculture, scoring a achievement by means of quality of goods and honesty in company”, our goods have been dependable by clientele and have received a more substantial share of market place.

Merchandise Description

Merchandise Description:

We specialised in manufacturing car gears , bike gears, gearbox, specific automobile (power takeoff, snowmobiles, engineering autos) gears, generator components, stainless steel ice crusher and so on.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Approach |

Equipment Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1., 1.twenty five, 1.5, 1.seventy five, 2., 2.25, 2.5….8. and so on. |

|

Warmth Therapy |

Carburizing & Quenching, Carbonitriding |

|

Normal |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Best China manufacturer & factory factory in Bogota Colombia manufacturer for High quality miniature gears gear bevel With high quality best price

Meanwhile, our products are manufactured according to hOur factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China. igh quality standards, and complying with the international advanced standard criteria.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product Keywords:

-

miniature gears,miniature gear,miniature bevel gear

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

Online Customization

To address these sealing and efficiency issues, Emerson Power Transmission (EPT) developed several design and manufacturing recommendations. The resulting gearboxes tend to run cooler and leak free, compared with conventional worm gear units.

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

Product Description:

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

The EPG GROUP range of PTO shafts accessories includes various types of yokes for the connection of the tractor power take-off with recessed push button and/or ball collar and/or ball collar for constant velocity joints, with the following spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20

The EPG GROUP range of PTO shafts accessories includes various types of yokes for the connection of the tractor power take-off with recessed push button and/or ball collar and/or ball collar for constant velocity joints, with the following spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20